What is the difference between GEL, AGM and Flooded batteries?

- Wet or flooded batteries do not have special pressurized sealing vents as they are not valve-regulated and do not work on the valve-regulated recombination principle.

- Wet batteries contain excess liquid electrolytes that can spill and cause corrosion if tipped or punctured. AGM and GEL batteries do not.

- Wet batteries are not air transportable without special containers, and they cannot usually be shipped via Express Courier or Parcel Post. AGM and GEL batteries have no DOT restrictions.

- Wet batteries should not be used near sensitive electronic equipment as the off-gassing can cause corrosion within the electrical circuits.

- Wet batteries can only be installed “upright.” AGM and GEL batteries can be installed on their sides. But not upside down!

- Because of the cost in time (man-hours), service products (distilled water etc.), damaged clothing, and polluted environments when being charged and/or discharged, wet batteries may end up costing more money to own over the life of the battery than do quality VRLA DRY CELL AGM or GEL batteries.

- Some brands of wet or flooded automotive batteries are also marketed and sold as sealed or maintenance-free. However, they are still flooded cell batteries - not “acid-starved” - and they DO NOT have the same pressurized venting system and will spill electrolyte if not kept upright.

- Because of acid stratification, wet batteries lose capacity and become permanently damaged if:

- Left in a discharged condition for any length of time due to acid stratification and the resulting sulfation. This is especially true for High or Low Antimony and/or Hybrid types.

- They are continually over-discharged or used in a PSOC. This is especially true for automotive starting types and “so-called” dual purpose Marine/RV combination cycling/starting batteries that many manufacturers are now selling as low-cost alternatives to true Deep Cycle batteries in leisure RV/Marine applications

Acid stratification is accelerated if:

- the battery operates in a partial state of charge (PSOC)

- the battery seldom receives a full charge

- the battery is constantly micro-cycled between 3% - 17.5% DOD as in start-stop vehicles

- the battery is regularly high cycled between 17.5% and 30%

- the battery is regularly deep-cycled beyond 50% DOD

- the battery is used or exposed to extreme temperatures, and

- the battery is left standing for long periods.

All of these conditions contribute to premature battery failure.

- AGM and GEL batteries do not suffer from Acid Stratification to the extent that wet-flooded batteries do. Because AGM and GEL technology completely absorb and constrains the acid in a woven glass fibre separator or silicate, it makes it more difficult for the acid to diffuse out from the water to accumulate at the bottom of the battery’s cells. This restrained diffusion has been proven to slow the stratifying effect of gravity on battery acid in DRY CELL AGM and GEL battery technology. Acid Stratification is the #1 killer of flooded lead-acid batteries.

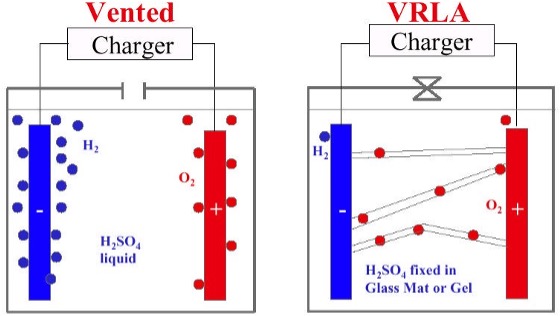

- A key feature of AGM and GEL batteries is the process of recombination of oxygen during the charging process. The cycle starts at the positive plate. Water is broken down, and gaseous oxygen is formed. The hydrogen ions remain dissolved in the electrolyte and are not released as gas as in wet FLOODED batteries. What happens to the oxygen as it makes its way to the negative plate is different in wet FLOODED batteries than in an AGM or GEL battery.

- In a wet or flooded lead-acid battery, it is practically impossible for the oxygen to move to the negative plate. Immediately after leaving the positive plate, it bubbles up and escapes through the vent plug.

- In DRY CELL AGM and GEL batteries, a densely porous medium is offered to the oxygen to facilitate its movement. The porous medium in an AGM Dry Cell battery is the woven fibreglass mat. The porous medium in a GEL Dry Cell battery is the cracks in the GEL electrolyte.

Figure 1 compares wet flooded vented battery gassing and VRLA DRY CELL AGM and GEL battery recombination.

Figure 1 - Vented Battery Gassing and VRLA DRY CELL Battery Recombination.