What is Constant Current (CC) charging?

Constant current (CC) charging initially allows the full current of the charger during the BULK stage to flow into the battery regardless of the battery state of charge or the temperature until the battery terminal voltage reaches a preset steady state. The battery is now in a state of charge of >80%

Constant current (CC) charging requires the initial charge current to be limited to a % of the battery’s capacity to avoid unnecessary gassing.

NOTE: Manufacturers publish different current limits for the BULK charge phase of a CC charge curve:

- 13% of the C20(15%C5) rating for flooded Deep Cycle.

- 15% of the C20(20%C5) rating for general-purpose GELL Deep Cycle.

- 25% of the C20 (30%C5) rating for Semi-traction industrial Deep Cycle AGM batteries.

- 25% of the C20(30%C5) rating for Semi-traction industrial Deep Cycle GELL batteries

- Up to 30% C20(35%C5) rating for high rate and thin plate AGM batteries.

The charge output then switches to a constant voltage ABSORPTION phase, during which the charging current tapers down due to the decreasing potential difference between the charger-output voltage and the battery terminal voltage, as described earlier in the section on constant voltage charging.

The current will continue to taper down until it falls to a low preset limit. This low limit - usually no more than 1% to 4% C20 of battery capacity, or a % of the initial charge current in the BULK charging phase – will be maintained for either a preset period (time wins over voltage) or by looking for voltage stability where the charge is terminated when the voltage fails to rise over a measured period (voltage wins over time).

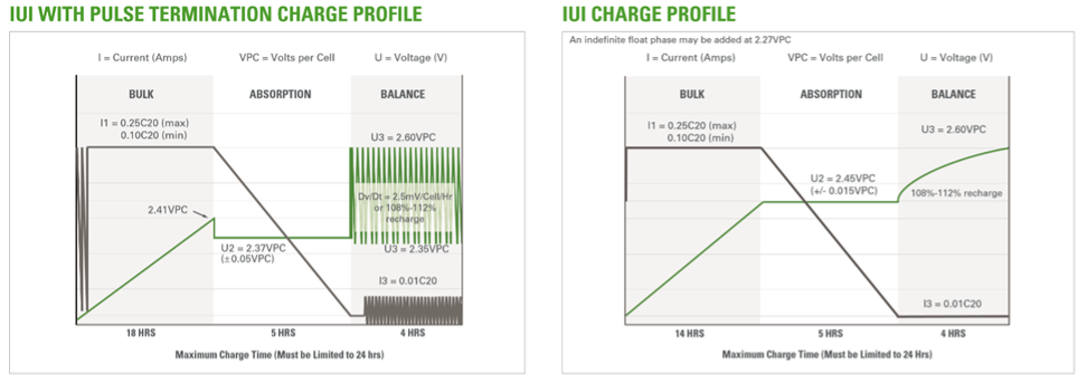

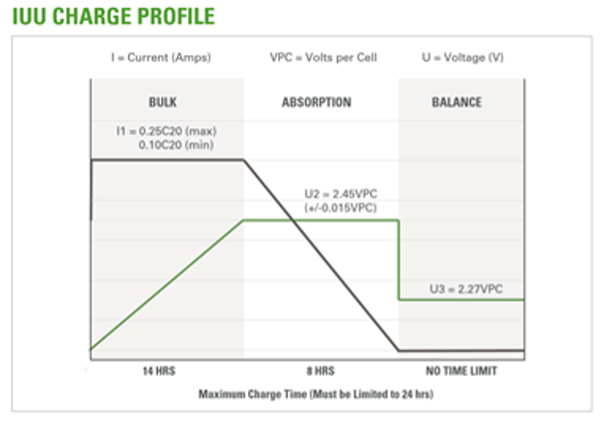

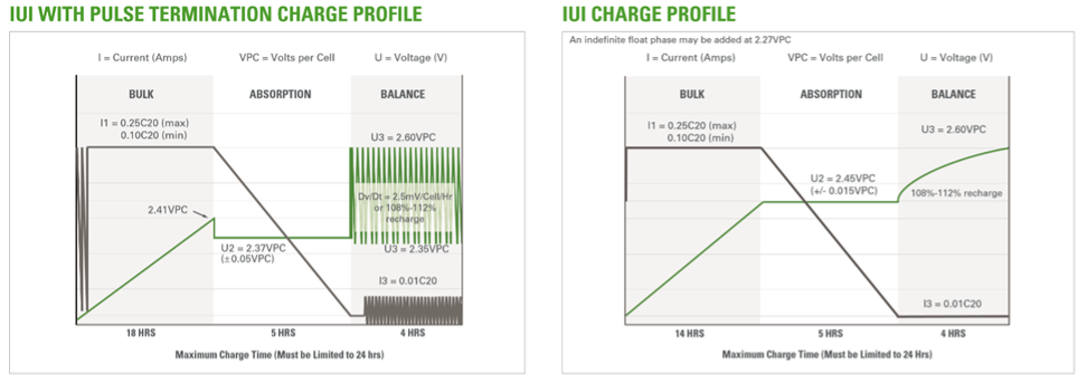

Finishing phases can be a simple float stage at a voltage below the batteries gassing voltage or a more highly engineered process that involves a special Balance and/or Pulsing mode shown in the graphs below for Discover Dry Cell AGM and GELL batteries.

When using a CC-charge regime

- the charge current should switch from a high (starting) charge rate to a tapering (finishing) rate when the battery reaches 95% to 100% state of charge.

- The point at which this switch occurs may be determined by using a mathematical algorithm timer (in smart switch mode chargers) or by sensing the battery voltage.

- The smart timer setting can be determined by calculating the time needed to return 108% to 112% of the ampere-hours drawn out for Semi-traction AGM or GELL batteries. However, this method should not be used unless the previously discharged capacity can be reliably and consistently measured using smart technology.

- The smart timer setting can be determined by calculating the time needed to return 105% to 110% of the ampere-hours drawn out for general-purpose AGM or GELL batteries. However, this method should not be used unless the previously discharged capacity can be reliably and consistently measured.

- The smart timer setting can be determined by calculating the time needed to return 115% to 125% of the ampere-hours drawn out for deep cycle flooded batteries. However, this method should not be used unless the previously discharged capacity can be reliably and consistently measured.

In theory, once approximately >95% of the previously discharged capacity has been returned during the bulk CC charge stage, a CV absorption stage will be continued at a constantly reducing charge current rate until approximately >100% of the previously discharged capacity has been replaced.

In reality, once it attains a theoretical 100% state of charge, it will continue to draw small currents to compensate for standing/parasitic and electro-chemical losses so that the needed overcharge is achieved.